China has had a pervasive impact on the global economy and each one of us. From electrical appliances to the lowly toothbrush, almost everything carries a “Made in China” label. How is China able to produce things so cheaply?

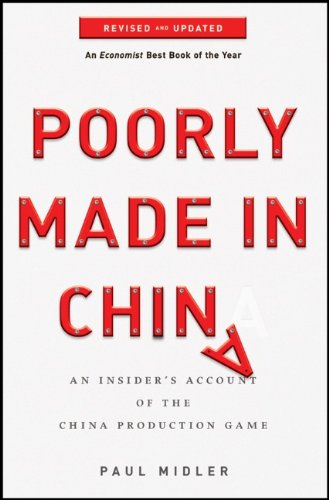

This is the key question Paul Midler tries to answer in his book “Poorly Made in China: An Insider’s Account of the Tactics Behind China’s Production Game”. Midler, an MBA from the Wharton Business School, has studied Chinese history, the Mandarin language, and resides in the southern city of Guangzhou, the manufacturing capital of China. He is employed as a local agent for American importers. Midler clearly has a unique window on the Chinese export machine.

In an entertaining narrative, Midler reaches the conclusion that the Chinese manufacturers achieve their margins by compromising on quality, aptly termed as the “quality fade”. The manufacturers squeeze costs by shrinking the labels on bottles or shockingly even altering the chemical composition of products. The trick is to do it without the Western importer finding out. Even if the importer does find out, the Chinese manufacturer will then negotiate a discounted price for future orders to ensure the order flow does not stop.

In Midler’s tales of Chinese production woes, “Poorly Made in China” provides useful insights into the Chinese culture. A loss of face due to a product recall is very embarrassing for the Chinese manufacturer who obviously does not conduct proper quality control. The onus of quality control falls on the importer, which explains the sharp jump in outside quality inspectors in China and the easy availability of formaldehyde testing kits for checking furniture. Quality control is not cheap or easy. If an importer wants to know which alien ingredient has been added to his product specifications, the cost of the tests is often more than the price of the product. So why bother?

Most of us believe that China has had a deflationary impact on global trade. Midler argues to the contrary. Commodity prices are fixed at the national level in China so economies of scale do not work effectively. In a hilarious episode, Midler asks the manufacturer what the cost will be for a small consignment versus a ten times larger order and she says the price will be the same. Government scrutiny also becomes pronounced as the order size increase. This prompts the manufacturers to keep the operations fragmented. The author goes to the extreme in his skepticism by saying that the Chinese pride in the large size of their country includes exaggerating their population to attract Western firms.

“Poorly Made in China” also rails against the greed of the Western world in continuing to pursue the Chinese low price mirage despite the obvious quality issues. The reader feels the frustrations of the importer and the total helplessness Midler feels to improve things. However, it fails to address the question of why the land that invented paper and gunpowder is now rife with counterfeits and manufacturing by rote. The book also fails to explore if the margins of importers have actually been squeezed over the years. It would also be interesting to find out if the consumer using an inferior product from China even recalls what a “Made in America” item felt like from 20 years ago. The book should prove a useful guide for any importer venturing into China.

Buyer Beware!